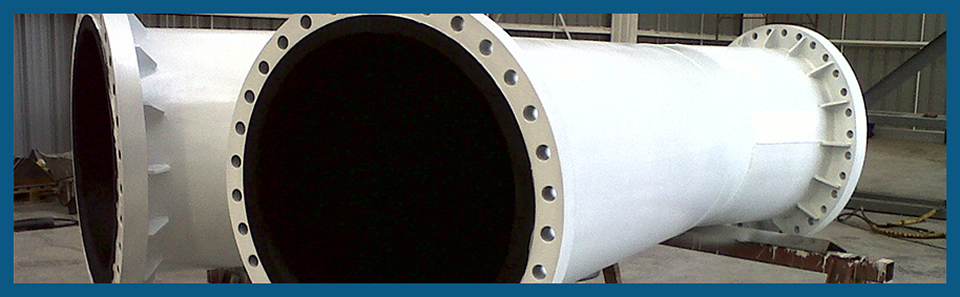

Polyethylene piping with steel core

< Back

Combining the qualities of metal and polyethylene piping, this material is indicated for plants, mining companies, oil companies and on sanitation, which conduct in their lines highly abrasive and corrosive products, field where the polyethylene features numerous advantages with regard to its chemical barrier, in addition to safely absorbing the pressure discharge in lines that require it, such work done by the carbon steel core of the piping.

Advantages

• Tubes with internal and external layers of polyethylene and inner lining in carbon steel, in addition to special parts and flanges with the same features.

• Low cost when compared to stainless steel, titanium and hastelloy.

• Resistance to corrosive solutions.

• Resistance to pressure discharge, not releasing the material and keeping its chemical barrier.

• Advantageous when compared to Epoxy paints.

Main Features

• Flanges from 32 up to 2000mm diameter, according to the B 16.5, AWWA and DIN international standards.

• Pipes up to 54” in 12m bars.

• Outer layer from 0.5 to 1.5mm.

• Inner layer up to 12mm.

• Spools (nipples) and manifolds respecting the same features of the piping.

• Special parts with non-standard drawings, since approved by our technical department.

Quality Control

The polyethylene lining services are conducted according to the current regulations and the quality control follows the specifications of those standards.

• Visual control, checking the homogeneous aspect and brightness.

• Ultrasound thickness measurement.

• Porosity detection using high-voltage equipment.

• Drying of parts at room temperature.